|

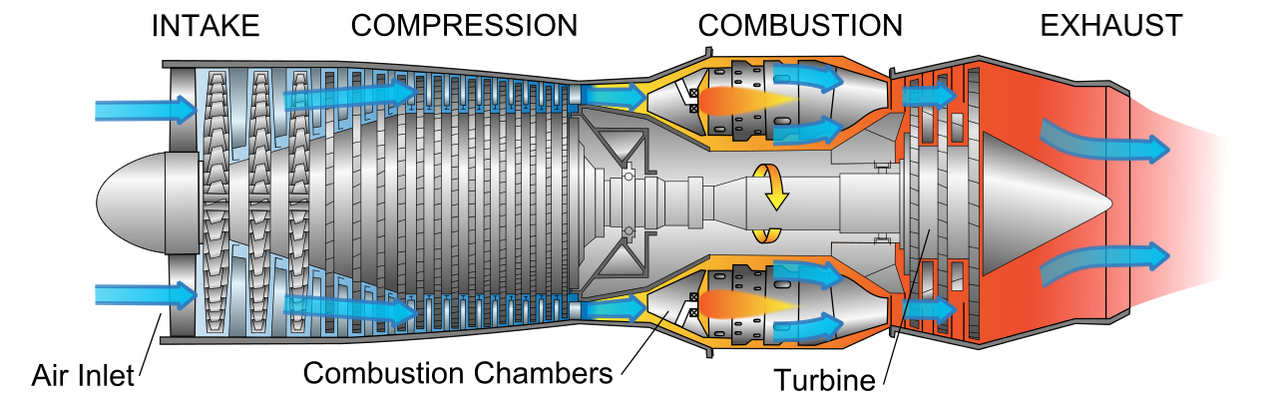

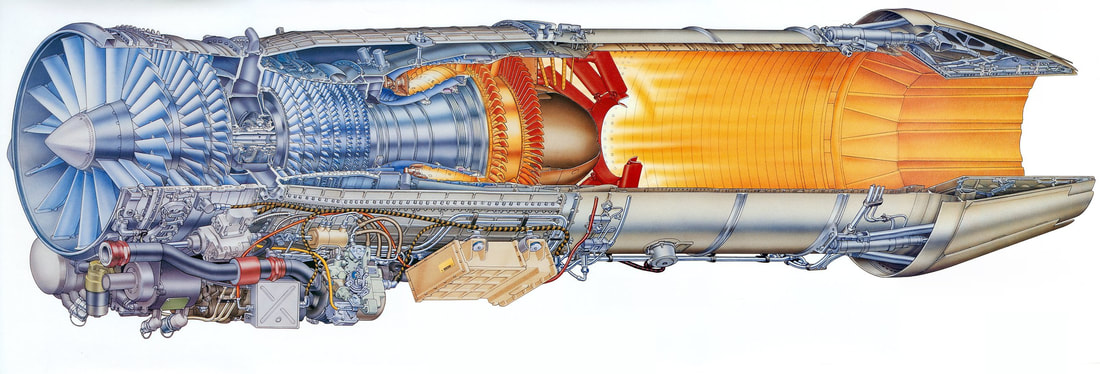

OBBI 141030Z 06007KT 020V080 9999 FEW030 35/22 Q1012 NOSIG An explosive billowing sound that reverberates with a rumble to shakes your disoriented self. A blunt impact of sound humbles you to attention. Your body is directed with shock towards this force of violence as it rips up the air with a roaring turbulent inferno. Behold the ominous force of an Afterburner jetting by! Flamed exhaust is expelled at a fearsome rate, resulting in amplified propelling power. A compounded force that adds to the engine’s processed air, expanding pressure to displace the craft with Newtons of force. [ Afterburner/Reheat - حارق لاحق ] is essentially a [ Ramjet - محرك نفاث تضاغطي ] attached to the back of a jet engine. The device uses a contained combustion chamber to magnify the directed exhaust out the other end. The heated air exiting the jet engine still holds enough oxygen to be exploited for thrust. Igniting fuel in this external Plenum chamber further expands the encapsulated gases, forcing them out of the chamber with thrusting power. Mainly used to achieve quick acceleration and improve thrust output. This calculated brute force provided a solution to the technical and material limitations of early Jet engine design. The need for such equipment relates back to the internal heat and pressure limitations of a Jet Engine and its parts. Within a Jet Engine, air is channeled through chambers of compression then rapidly expanded with ignited fuel in an unforgiving cycle of force. The heat created within these chambers can easy reach 2000°C risking meltdowns and blowouts. The pressure generated by rapid expansion of ignited gases, also adds to the engine's limitations. If left unchecked, the released forces could explosively compromise the engine and melt its parts. A limitation of material strength, and technological know-how bar the utility of more power. Hence the attachment of an external chamber. Reheating the existing air in a separate chamber allows for the added rocketing force to be utilized, without risking the structural integrity of the Engine. The awesomeness of this power is best seen at night, the resulting flame is brilliantly visible resembling a rocket plume. A closer look at this flame exposes diamond-like focal points that repeat in dissipating sequence. Impressively these Shock Diamonds are the result of pressure compression, relating to the difference between the supersonic gases expelled into the surrounding ambient air. They are also the main reason behind the thunderous sound. Rushing gases rip the surrounding ambient air in a turbulent frenzy, similar to the effect of a boat propeller in water. Another aspect yet more relative to engine performance is the visible coloration of the flame inside the chamber. A consequential relationship to the efficiency of combustion, results in a hue ranging from an orange to blue flame. Just like a [ Bunsen Burner - موقد بنزن ], the iconic orange afterburner plume stems from lower internal engine temperatures. Blue plumes are an indication that combustion is more efficient and holds a higher temperature. This is visibly evident when comparing the orange flames of an F-16 and the Blue burn of a Su-30. This coloration is a direct result of design preference and choice, rather than an advancement of technology and knowledge. Higher internal engine temperatures are better for an efficient fuel burn, but also comes at a higher pressure which can affect the durability of the engine itself. This relates directly to the maintenance and operational costs of the engine. For example, a F-16 with its P&W F100 engine requires an overhaul about every 7-10 years, where the Su-30 with its Saturn AL-31 Engines only last about 3-5 years between rebuilds. Fuel and engine material can also contribute to the coloration of the flame. For example, some experimental engines produce a green or violate plume relating directly to the stabilizing additives used in the fuel. This is more evident in rocket propulsion as the fuel they use is heavenly mixed with Oxidized Elements, usually Aluminum, Barium, or Germanium, but that's rocket science, not jet propulsion.  The German Me-163 of WWII The German Me-163 of WWII The idea of rocketing an aircraft was first realized with the German Luftwaffe of WWII. The Messerschmitt Me-163 Komet was literally a rocket engine attached to the end of a micro aircraft. The Germans used this aircraft to rapidly blast pilots up to intercept incoming bombers. These were extreme aircraft with extreme tolerances for an extreme time in history. The Komet utilized the explosive reaction of two separate fuels and was notorious for exploding before Takeoff, sometimes even when taxiing or fueling. The extremely volatile and toxic fuel was highly corrosive. The risking of leaks or unintended mix of fuels added to the dangers of this Hyperbolic Propellant. Even after a successful mission and fuel tanks empty, the remnant fumes were volatile enough to make landings a form of grace from God! Obviously, this was not a solution. Jet technology was still in its infancy, unreliable and under powered, Jet engines continued to struggle with lifting loads and acceleration. Piston Prop engines were still the preferred and more economic choice to power aircraft. By the mid-1940s the British "with a stiff upper lip" developed the first Jet Augmentation device and called it Reheat. Although they never actually built a usable full-scale system, the concept reached major milestones in development as they experimented with Mach speeds and its propulsion.

Even though the small A318 engine produces an excess of 90 kN. Keeping in mind that Commercial Jet engines work on a complete different scale relative to size, endurance, efficiency, load, and power response. Afterburners with their barbaric approach to power later allowed aircraft to reasonably utilize thrust, reaching speeds that exceed Mach 3. This also meant that a lot of fuel was spent achieving this thrust, limiting gained acceleration to bursts of power rather than sustained flight. Most notable was the magnificent Concorde, using Reheat only to achieve quicker takeoffs or to cross the transonic threshold. Its ability to travel 3,900 nm at Mach 2 Speeds was the raw result of four 140 kN of Rolls-Royce Power with le flair français! Known as [ Supercruise - طواف فائق ] the engines were meticulously designed to provide the needed power at a relatively economic fuel rate. Otherwise with Reheat 164 kN are produced by each engine, gulping a combined 32.5 liters per second. That's a medium fish tank every second! At that rate, the aircraft would run out of fuel within an hour of flight.

With nothing more than advanced bottle rocket technology, engineers struggle to achieve quiet and efficient higher speeds. So much that not even commercial greed can maintain the beloved Supersonic Speedbird. Even though still experimental in application. Recent structural design developments have allowed for aircraft to move with relatively less turbulence and drag, reducing Sonic Booms to a mere Thump. Engine output has massively increased, with even higher fuel efficiency, reducing travel and maintenance costs.

As with the electric silence of cars, a day will come when aircraft will be able to comfortably leave sound behind without a roar. This barbaric approach of directed explosions will be tamed and nerfed. I for one would love to experience that raging power before we make our silent leap forward!

0 Comments

Leave a Reply. |

38AB

The Aviator.. Flight Recorder

May 2019

Departments

|

Services |

Management |

Copyright © 2018 bahrainaviators.com

|

RSS Feed

RSS Feed